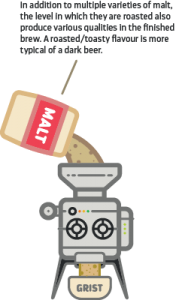

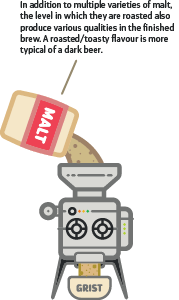

MILLING

Malts are milled together to break up kernels to extract sugar for fermentation. This sugar feeds the yeast in the fermenting stage, producing alcohol, CO2 & flavouring. Milled malt is called grist.

Barley and wheat are the most common grains used in brewing, but alternatives such as rye and oat can be used as well.

Different types of malts and roasting levels help achieve specific flavours depending on the intended beer style.

WATER TANK

No water means no beer! Having tanks stocked up and ready to go for each new brew is essential to maintaining a consistent workflow.

We source our water locally from glacial runoffs and lakes in the region to really deliver a genuine taste of Lillooet.

Water is also used to cool the wort as it’s transferred from the Kettle-Whirlpool to the fermenter through channeling pipes for the cold water to remove heat from the brew.

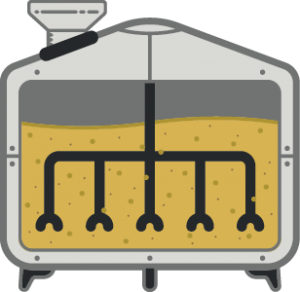

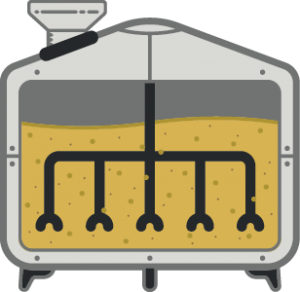

MASH-LAUTERING

Our process utilizes a 2-vessel system, meaning the mashing and lautering happens in the same vessel.

Mashing: Mixing the malt and warm water extracts fermentable sugars and proteins. This step helps determine the body and dryness of the finished beer & sets up the wort for the lautering process.

Lautering: After roughly 1 hour, the water, sugar & proteins, now called Wort, is filtered from the grain bed and transferred to the Kettle-Whirlpool. The spent grains are separated and left behind.

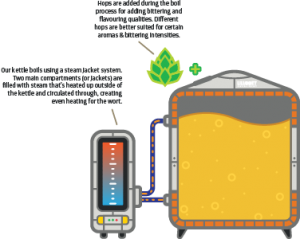

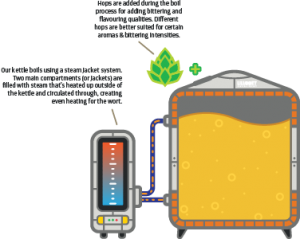

KETTLE-WHIRLPOOL

Our Brewing Kettle is a 2-vessel system, including the whirlpool step (hence the name).

Brewing/Boiling: Hops, lactose (milk sugars) & spices (such as orange peel and coriander) can be added in at different times during the boil to affect the flavour, aroma & consistency of the finished beer. The boiling takes approx. 1-1.5hrs long depending on how much evaporation and, consequently, concentrating of the wort is desired.

Whirlpool: After the boil is complete, the boiled wort is spun around the vessel causing any solids such as hops, barley & proteins to settle in the center of the vessel in the shape of a cone called the “trub cone”.

Fun Fact:

Incidentally, this process (described by Albert Einstein whilst stirring his tea and observing the tea leaves) is called the Teacup Effect; It works because the friction of the wort against the sides of the vessel creates opposing areas of high and low pressure, causing the wort to circulate vertically as well as in a rotary motion, depositing all the solids in a nice neat cone in the center.

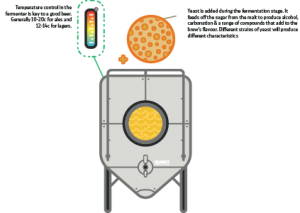

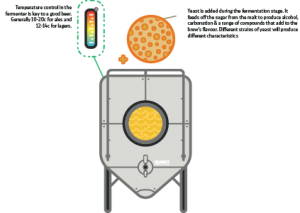

FERMENTER

Yeast is added to the cooled wort to begin the fermentation phase (it’s very important the wort is cooled. Hot wort kills yeast!)

Yeast: (Saccharomyces Cerevisiae) a single celled organism classified as a fungus. The yeast converts the sugar into alcohol as well as producing Carbon Dioxide & a palate of flavours.

Most of the maturation of the brew happens here. As the beer ferments and the yeast “flocculates to the bottom of the cone” the yeast will be drawn off the bottom of the cone and “taken off the beer”. This prevents unwanted flavours from the autolysing (dying & decomposing) yeast to develop. Most of the beer’s maturation is complete by the time it is ready to be transferred to a Brite Tank.

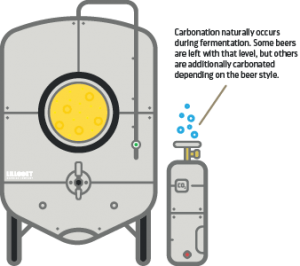

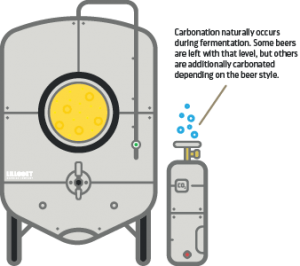

BRITE (SERVING) TANKS

Once the fermenting stage is complete, the beer is transferred to a BBT (Brite Beer Tank). The beer has some natural carbonation from the fermentation stage, but additional CO2 is added in the brite tank to bring the brew up to the desired level of carbonation.

The beer is ready to serve! (Certain specialty beers, like Marzens, have longer maturation processes). Lillooet Brewing has 6 Brite tanks that are connected to the brewery’s frontend taps in the taproom for pints and growler fills.

FILLING STAGE

BBTs are also used to fill cans, bottles & kegs. Cans & bottles are found in the brewery for off-sales and distributed throughout the region to a variety of licensed liquor stores. Kegs are filled for storage and distribution for parties, restaurants & pubs.

MILLING

Malts are milled together to break up kernels to extract sugar for fermentation. This sugar feeds the yeast in the fermenting stage, producing alcohol, CO2 & flavouring. Milled malt is called grist.

Barley and wheat are the most common grains used in brewing, but alternatives such as rye and oat can be used as well.

Different types of malts and roasting levels help achieve specific flavours depending on the intended beer style.

WATER TANK

No water means no beer! Having tanks stocked up and ready to go for each new brew is essential to maintaining a consistent workflow.

We source our water locally from glacial runoffs and lakes in the region to really deliver a genuine taste of Lillooet.

Water is also used to cool the wort as it’s transferred from the Kettle-Whirlpool to the fermenter through channeling pipes for the cold water to remove heat from the brew.

MASH-LAUTERING

Our process utilizes a 2-vessel system, meaning the mashing and lautering happens in the same vessel.

Mashing: Mixing the malt and warm water extracts fermentable sugars and proteins. This step helps determine the body and dryness of the finished beer & sets up the wort for the lautering process.

Lautering: After roughly 1 hour, the water, sugar & proteins, now called Wort, is filtered from the grain bed and transferred to the Kettle-Whirlpool. The spent grains are separated and left behind.

KETTLE-WHIRLPOOL

Our Brewing Kettle is a 2-vessel system, including the whirlpool step (hence the name).

Brewing/Boiling: Hops, lactose (milk sugars) & spices (such as orange peel and coriander) can be added in at different times during the boil to affect the flavour, aroma & consistency of the finished beer. The boiling takes approx. 1-1.5hrs long depending on how much evaporation and, consequently, concentrating of the wort is desired.

Whirlpool: After the boil is complete, the boiled wort is spun around the vessel causing any solids such as hops, barley & proteins to settle in the center of the vessel in the shape of a cone called the “trub cone”.

Fun Fact:

Incidentally, this process (described by Albert Einstein whilst stirring his tea and observing the tea leaves) is called the Teacup Effect; It works because the friction of the wort against the sides of the vessel creates opposing areas of high and low pressure, causing the wort to circulate vertically as well as in a rotary motion, depositing all the solids in a nice neat cone in the center.

FERMENTER

Yeast is added to the cooled wort to begin the fermentation phase (it’s very important the wort is cooled. Hot wort kills yeast!)

Yeast: (Saccharomyces Cerevisiae) a single celled organism classified as a fungus. The yeast converts the sugar into alcohol as well as producing Carbon Dioxide & a palate of flavours.

Most of the maturation of the brew happens here. As the beer ferments and the yeast “flocculates to the bottom of the cone” the yeast will be drawn off the bottom of the cone and “taken off the beer”. This prevents unwanted flavours from the autolysing (dying & decomposing) yeast to develop. Most of the beer’s maturation is complete by the time it is ready to be transferred to a Brite Tank.

BRITE (SERVING) TANKS

Once the fermenting stage is complete, the beer is transferred to a BBT (Brite Beer Tank). The beer has some natural carbonation from the fermentation stage, but additional CO2 is added in the brite tank to bring the brew up to the desired level of carbonation.

The beer is ready to serve! (Certain specialty beers, like Marzens, have longer maturation processes). Lillooet Brewing has 6 Brite tanks that are connected to the brewery’s frontend taps in the taproom for pints and growler fills.

FILLING STAGE

BBTs are also used to fill cans, bottles & kegs. Cans & bottles are found in the brewery for off-sales and distributed throughout the region to a variety of licensed liquor stores. Kegs are filled for storage and distribution for parties, restaurants & pubs.

Growlers Care

Full Growlers

- Make sure your cap is tight.

- Do not leave in direct sun.

- Keep cold.

- Consume in a day.

Empty Growlers

- Keep capped until you rinse.

- Rinse thoroughly with HOT water.

- Throw the cap away.

- Air-dry upsidedown.